Solar Panel Wiring Tips Every Throop Homeowner Should Know

Solar energy slashes utility costs and benefits the environment. Quality electrical work makes the difference between a successful investment and constant problems. Learning photovoltaic basics helps you ask smart questions and spot issues before they become expensive.

Why Quality Solar Electrical Work Matters

Your solar electrical network connects rooftop arrays to household power. Sunlight striking panels generates electricity that flows through designed pathways to energize appliances and devices. Poor junction quality wastes energy, damages equipment, and creates hazards.

Beyond performance, correct setup protects manufacturer warranties. Companies deny claims when work fails code standards. Professional craftsmanship ensures reliable generation for 25 years or longer.

Array Configuration Options

Series Setups

Series arrangements link modules end-to-end. One unit's positive terminal connects to the next unit's negative terminal. This boosts voltage while current stays steady.

Benefits: Higher voltage reduces loss over long distances. Fewer junctions mean fewer potential failure points.

Drawbacks: One underperforming module drags down the entire string. Cloudy conditions impact output more when units receive uneven light.

Parallel Setups

Parallel arrangements join all positive terminals together and all negative terminals together. Current increases while voltage remains constant.

Benefits: Individual module problems don't affect others. Performance stays stronger when shadows hit different areas at different times.

Drawbacks: More junctions create additional failure opportunities. Lower voltage can increase loss over distance.

Combined Approach

Most residential setups blend both methods. Modules link in series forming strings, then strings connect in parallel. Combining both approaches optimizes performance for Throop, PA's variable weather patterns.

Selecting Proper Components

Conductor Sizing

Conductor gauge controls current flow safely through cables. Thicker conductors (lower gauge numbers) handle more power with minimal resistance.

Typical home systems use 10 AWG or 12 AWG conductors between array components. Larger setups may need 8 AWG. Your choice depends on output and distance.

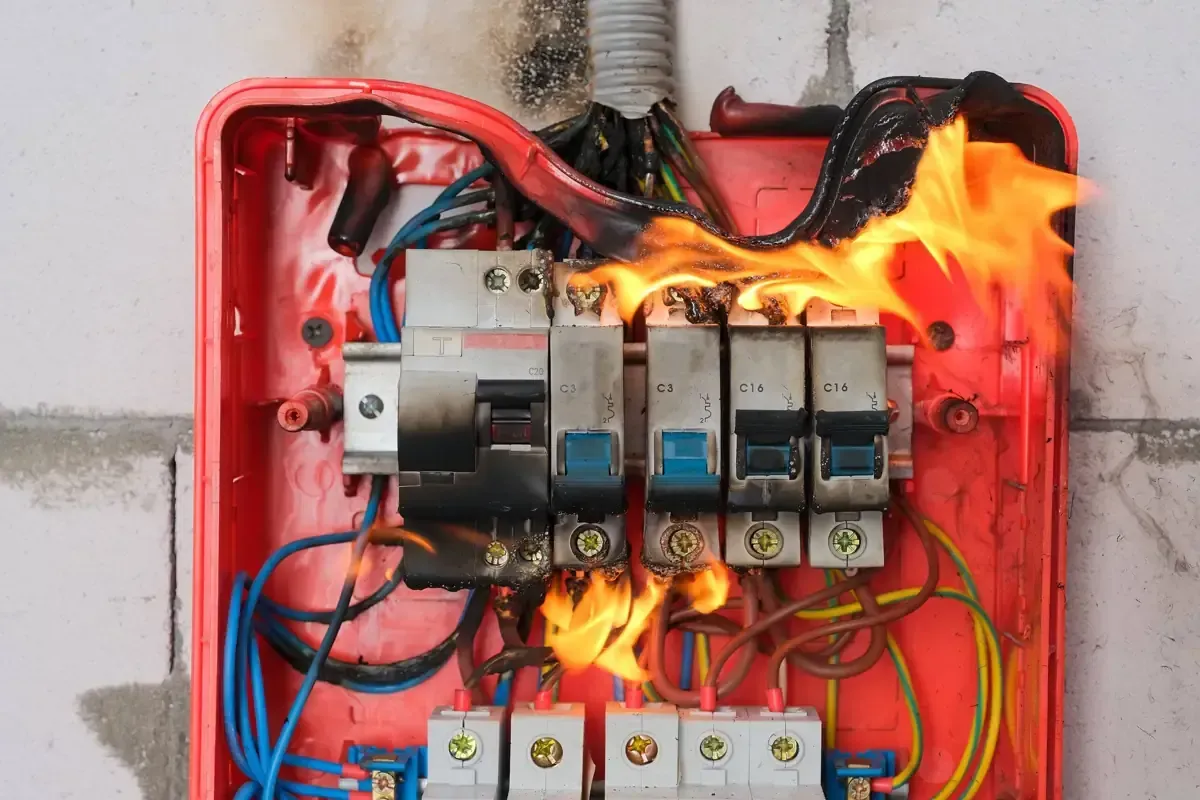

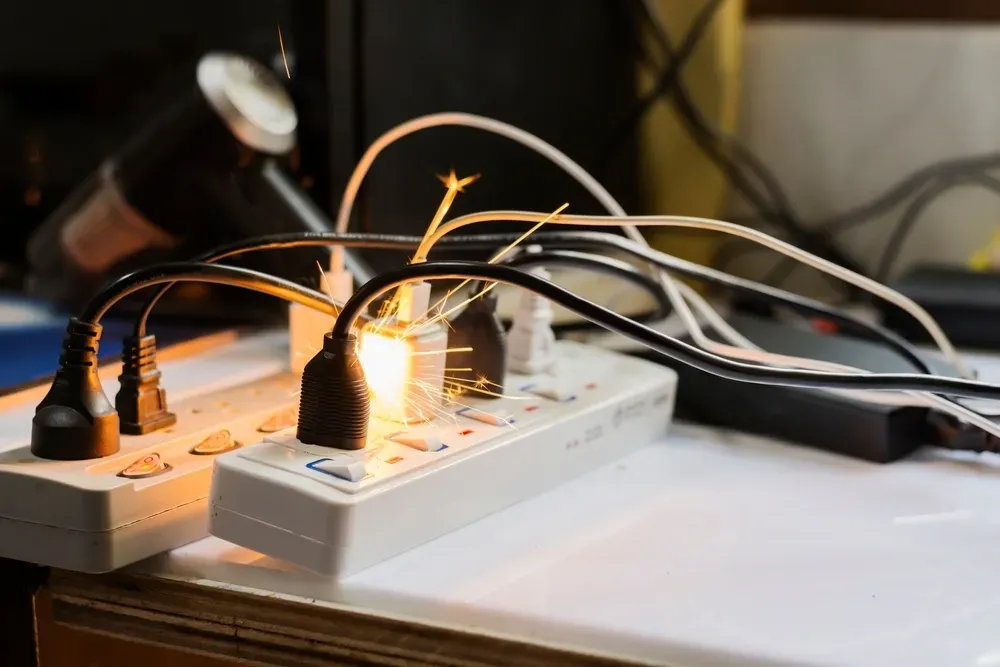

Undersized conductors generate excessive heat and voltage drops. Array output decreases while fire danger increases. Follow National Electrical Code standards and manufacturer specifications.

Conductor Types

PV Cable: Built exclusively for photovoltaic applications with UV-resistant insulation and moisture protection. Rated from negative 40°F to 194°F, ideal for Pennsylvania's temperature swings.

USE-2 Cable: Required for underground runs connecting arrays to main electrical panels. Protects against moisture and soil contact, important in Throop, PA where ground conditions vary.

THHN/THWN Cable: Works well inside conduit for protected runs but lacks UV resistance for exposed sections.

Safety Practices and Common Installation Errors

Understanding proper protocols and typical mistakes helps you evaluate contractor quality and maintain your system correctly.

Power Disconnection First

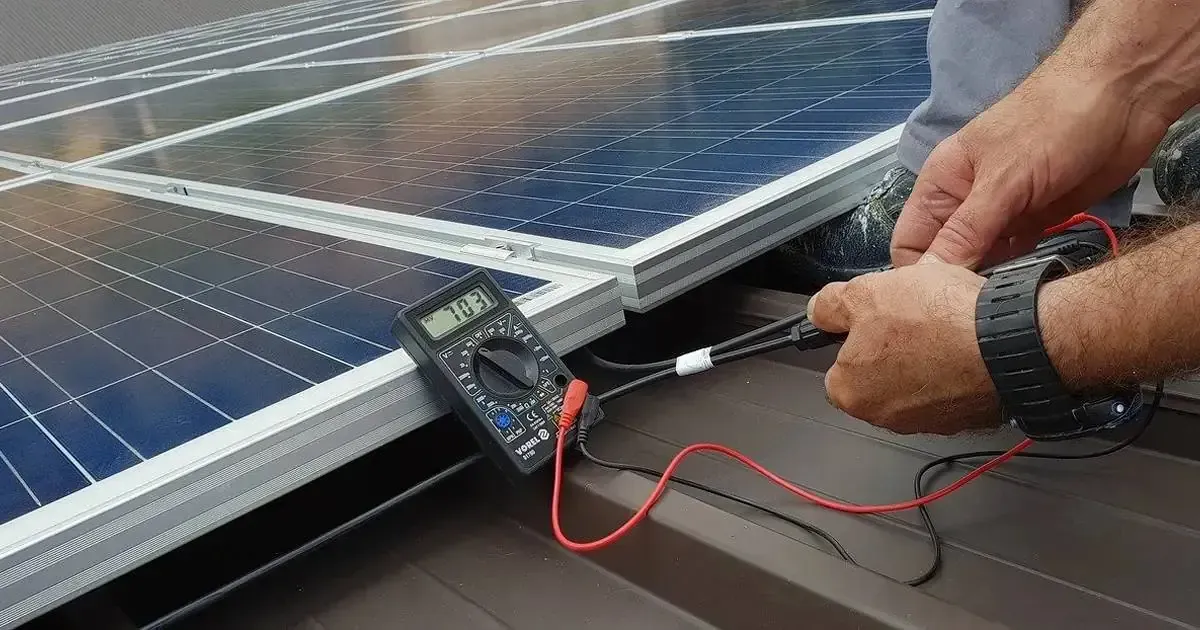

Arrays create electricity in any light, including overcast conditions. Switch off power at the combiner box or inverter before handling connections. Verify with a multimeter rather than guessing to prevent potentially fatal shocks.

Lightning Protection

All metal components need grounding to defend against shocks and lightning strikes. Pennsylvania thunderstorms make grounding especially important. Ground frames, mounting hardware, junction boxes, and inverter cases properly.

Secure Setup and Routing

Weak junctions generate resistance, creating heat and wasting power. Use MC4 connectors between array components. These industry-standard devices lock firmly and withstand weather.

Plan routing avoiding sharp corners and foot traffic. Use conduit for exposed sections, particularly where cabling crosses roofs or walls. Fasten cables regularly preventing wind damage. Allow slack for temperature expansion while avoiding sags.

Material Consistency

Never mix conductor sizes or types in single circuits. Mismatched components create weak points where resistance builds and failures occur.

Weather Protection

All exterior junctions demand waterproof shields. Moisture triggers corrosion, shorts, and equipment breakdown. Use waterproof boxes and seal conduit openings with proper fittings. Pennsylvania's rain, snow, and humidity make weatherproofing critical.

Code Compliance

National Electrical Code establishes baseline requirements. Current regulations mandate rapid shutdown features and arc fault protection for homes. Every component needs clear labeling showing voltage levels and warnings.

Critical System Components

Power Inverters

Inverters convert DC electricity from arrays into AC electricity appliances use. String inverters manage multiple modules simultaneously, while microinverters attach to individual units. Your electrical design varies based on inverter selection.

Combiner Boxes

Combiner boxes gather cabling from several modules before directing power to inverters. They contain protective fuses or breakers guarding against overloads.

Disconnect Switches

Disconnect switches let you safely cut power from arrays. Regulations require clearly marked disconnects accessible to emergency responders.

Hiring Professional Help

Certified technicians determine precise voltage, amperage, and conductor specifications for your circumstances in Throop, PA. They evaluate module positioning, shade patterns, roof design, and municipal codes, preventing costly mistakes while ensuring optimal performance.

Solar projects need construction permits and reviews. Professionals know local standards and get approvals without delays. They manage paperwork and coordinate with officials. Licensed contractors maintain insurance for safe high-elevation work with dangerous DC voltage, and their work preserves equipment warranties that self-installation typically voids.

Year-Round Maintenance Guide

Inspect visible cabling quarterly for deterioration, rust, or loose fittings. Look for discolored insulation, melted coatings, or scorch marks near junctions. Watch for warning signs: humming from boxes, warm cable sections, or dropping generation levels. Track daily output through your monitoring interface since unexpected production decreases might indicate hidden problems even when everything looks normal.

Pennsylvania's weather extremes stress connections year-round. Spring storms, summer heat, fall winds, and winter freezes all take their toll. After severe weather, examine outdoor work carefully. Clean accessible junctions during routine upkeep, removing dirt and debris that increase resistance. Confirm all fasteners stay tight and seals remain intact.

Keep vegetation trimmed continuously preventing shading and physical damage to components. Branches can damage insulation or stress attachment points during storms. Before harsh weather arrives, verify weatherproof seals work properly and drainage stays clear. Temperature fluctuations loosen hardware, so regular checks ensure nothing has compromised your setup.

Setup Enhancement Strategies

Distance Reduction

Shorter paths decrease voltage loss and boost efficiency. Locate combiner boxes and inverters to minimize spacing between components. Reduced distances raise performance and cut material costs.

Growth Planning

Build your framework anticipating possible expansion if you might add capacity later. Larger conduit and extra combiner capacity simplify future improvements and reduce costs.

Light Pattern Matching

Cluster modules getting comparable sun exposure when feasible. Matching light patterns elevates efficiency, particularly in series arrangements where one shaded unit impacts the complete string. Consider local weather patterns when planning placement.

Understanding Power Fundamentals

Current Types

Solar arrays create DC (direct current) power. Your residence operates on AC (alternating current) power. Inverters manage this transformation, but all cabling before inverters needs DC approval.

Voltage Factors

Higher voltage setups need lower amperage for identical power production. Lower amperage permits smaller conductor sizes. But higher voltages demand stricter safety measures and stronger insulation.

Amperage Limits

Each conductor and junction has maximum amperage capacity. Exceeding limits causes overheating and fire danger. Always size components for minimum 125% of peak anticipated current, providing safety cushion.

Protect Your Solar Investment

Quality electrical work turns arrays into reliable, efficient energy sources. Understanding these basics helps you ask informed questions and recognize skilled craftsmanship when you see it.

Your solar project represents a substantial commitment to your property and energy independence. Proper setup from the start makes the difference between decades of trouble-free service and constant repairs.

Ready to install solar panels in Throop, PA? Contact Bee-lectric today. Our certified technicians specialize in photovoltaic work, ensuring your system meets safety standards, operates efficiently, and delivers lasting performance.